LED unit board has many usages. LED full-color displays are composed of the most basic LED unit boards, not only full-color displays, but also other conventional displays. If there is a problem with the unit board, it will directly lead to the display effect of the entire full-color display screen, or even directly cause a black screen phenomenon, so it is very important to effectively distinguish the quality of the full-color display unit board. How to distinguish the quality of LED full-color display unit boards has become a concern of many manufacturers. Friends can consider from the following aspects.

1. IC devices

The brand of the IC device is very important. In the later stage, we will consider what type of IC we use and how many ICs we use, whether we use more or less, which will greatly affect the quality of the LED unit board. Even a small number of LED display manufacturers will deliberately reduce the number of IC devices when producing unit boards in order to save costs, or use irregular miscellaneous brand IC devices, which is very unfeasible.

2. LED lamp beads and chips

As for whether the lamp beads on the LED unit board are good or bad, our naked eyes cannot judge them. Only by long-term multiple tests can we judge. For non-regular display manufacturers, before leaving the factory, the products will be powered on to check whether the display can work normally, but they will not go through a long-term aging test, because the long-term aging test will affect the manpower and material resources of the manufacturer.

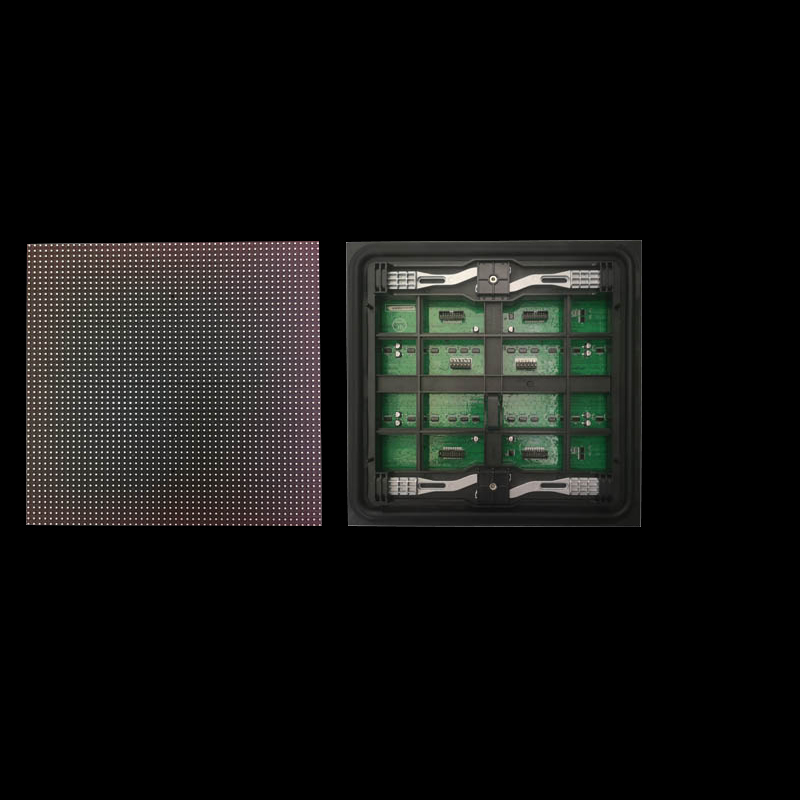

3. Welding quality

Welding refers to checking whether the patch on the LED unit board has components missed or wrongly pasted, whether there are burrs and short circuits on the component pins, etc., checking whether the solder joints of the direct plug-in are smooth and round, whether the board surface is clean and tidy, and there is no missing soldering or missing soldering . Also check the flatness of the light-emitting dot matrix and the consistency of the ink color.

4. LED unit board material

In recent years, many LED unit board manufacturers have adopted cheap flame-retardant paper board materials or single-sided fiber boards as PCB circuit boards for LED lights in order to compete for more customers at low prices. People who don’t know how to use it may not feel any difference, because there will be no difference when they first use it. However, after a few months of use, it is prone to various problems such as moisture, ultraviolet damage, oxidation, and oxidative fracture, which will easily lead to the scrapping of the entire LED unit board. Regular display unit boards use double-sided full glass fiber PCB boards. Although the cost is relatively higher, it is more secure for users to use in the future.